Page Not Found

Page not found. Your pixels are in another canvas.

A list of all the posts and pages found on the site. For you robots out there is an XML version available for digesting as well.

Page not found. Your pixels are in another canvas.

About me

This is a page not in th emain menu

Published:

Common usages for Raspberry Pi in IoT applications

Published:

Concepts and equations used in the Frenet Frame path planner

Published:

Explanation of coordinates used in RTK GPS solutions

Published:

Published:

Published:

”

”

Published:

Published:

Published:

Published:

Published:

Published in Computers and Electronics in Agriculture, 2020

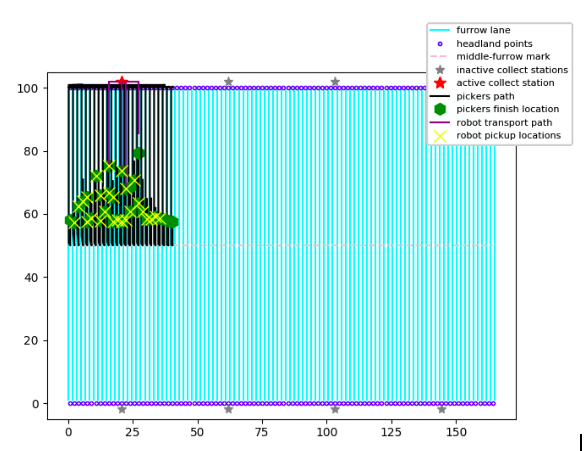

Some specialty crops, such as strawberries and table grapes, are harvested by large crews of pickers who spend significant amounts of time carrying empty and full (with the harvested crop) trays. A step toward increasing harvest automation for such crops is to deploy harvest-aid robots that transport the empty and full trays, thus increasing harvest efficiency by reducing pickers’ non-productive walking times.

Download here

Published in Computers and Electronics in Agriculture, 2020

In Part I of this work, a modeling framework, and a stochastic simulator were presented for all-manual and robot-aided harvesting. This paper reports Part II of our work, which utilized data gathered in two strawberry fields during harvesting, to estimate the stochastic parameters involved in modeling pickers, and evaluate the prediction accuracy of the simulator for all-manual picking. Then, as a case study, non-productive time and harvest efficiency were estimated for robot-aided harvesting, for various picker-robot ratios and three priority-based reactive dispatching strategies for the robots.

Download here

Published in Computers and Electronics in Agriculture, 2020

In this paper,dynamic predictive scheduling was modeled for teams of robots carrying trays during manual harvesting. The times and locations of the tray-transport requestswere assumed to be known exactly (deterministic predictions). Near-optimal scheduling was implemented to provide efficiency upper-boundsfor any predictive scheduling algorithms that incorporate uncertainty in the predictive requests. Robot-aided harvesting was simulated using manual-harvest data collected from a commercial picking crew. Scheduling performance was studied as a function of the number of robots, for a given crew size, and as a function of robot speed. Additionally, the effect of the earliness of the availability of the predictionson performance was studied.

Download here

Published in Jounal of Field Robotics (JFR), 2021

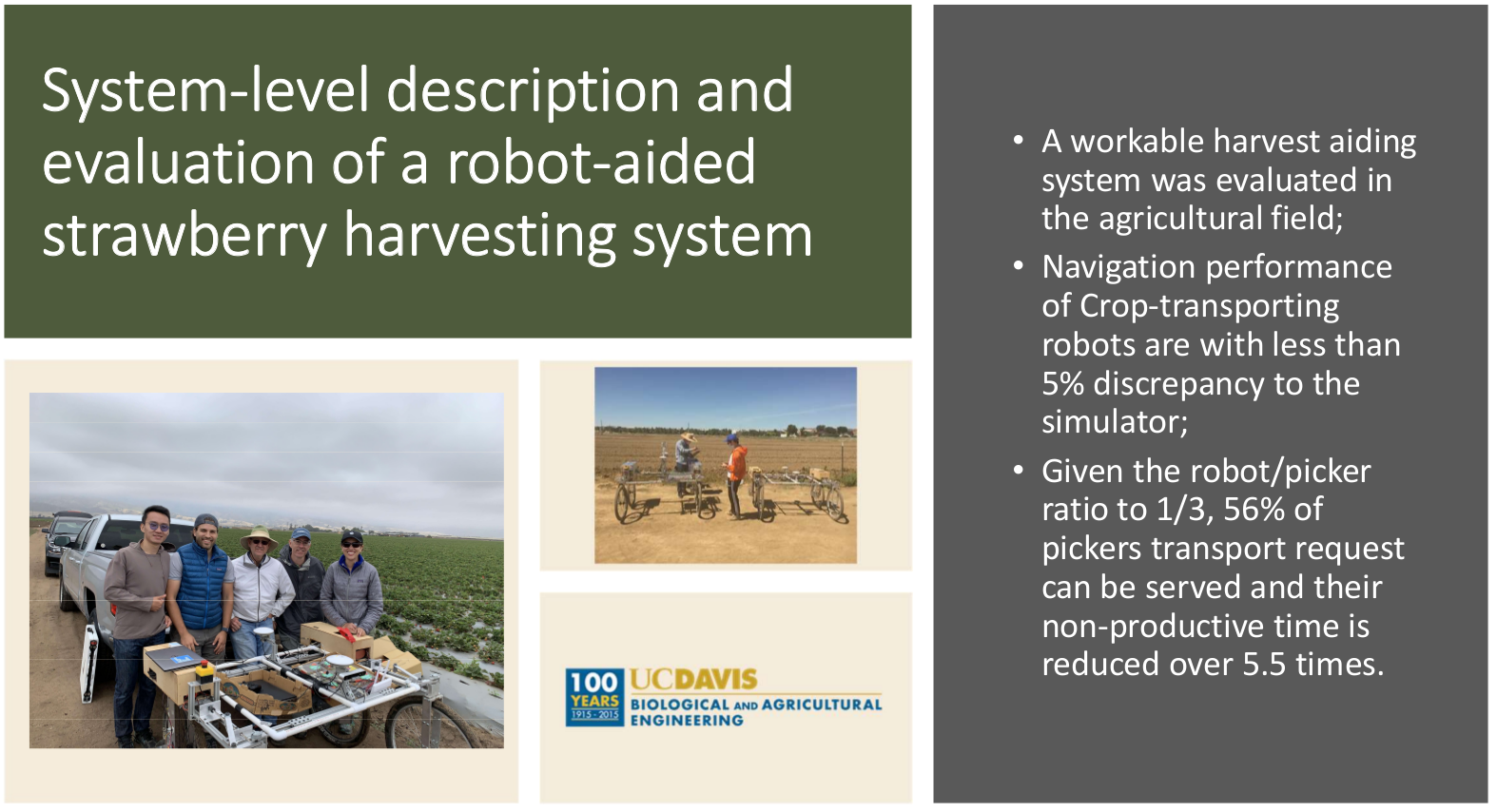

This work presents the implementation and integration of the co-robotic harvest-aid system and its deployment during commercial strawberry harvesting. The evaluation experiments demonstrated that the proof-of-concept system was fully functional. The co-robots improved the mean harvesting efficiency by around 10% and reduced the mean non-productive time by 60%, when the robot-to-picker ratio was 1:3.

Download here

Published in 2022 30th Mediterranean Conference on Control and Automation (MED), 2022

A robust navigation system is a prerequisite for a mobile robotic platform to carry out precision agriculture tasks in a modern orchard. In contrast to open fields, navigation based solely on the Global Navigation Satellite System (GNSS) is not stable in many orchards, where tree canopies may block the GNSS signal or introduce multipath. Many works have been done to localize the robot while traversing the inside a row, but navigating the robot to the next row on headland still relies on a reference map or artificial landmarks. In this work, we developed a row end detection method by exploiting drastic changes in the statistical distribution of points sensed by a depth camera compared to the points inside the row. Also, a robust way of row entry method is implemented by building a local environment map and reactive path tracker. The whole navigation system is tested and evaluated on a mobile robot in a vineyard. The experiment results show the robot can detect the tree row-end accurately and maneuver a U-turn to the next row safely.

Published in Machines, 2023

GPS-based navigation in orchards can be unstable because trees may block the GPS signal or introduce multipath errors. Most research on robot navigation without GPS has focused on guidance inside orchard rows; end-of-row detection has not received enough attention.

Download here

Published in Journal of Field Robotics (JFR), 2024

Headland maneuvering is a crucial part of the field operations performed by autonomous agricultural vehicles (AAVs). While motion planning for headland turning in open fields has been extensively studied and integrated into commercial autoguidance systems, the existing methods primarily address scenarios with ample headland space and thus may not work in more constrained headland geometries.

Download here

Published in IEEE Robotics and Automation Letter, 2025

Headland maneuvering is a crucial part of the field operations performed by autonomous agricultural vehicles (AAVs). While motion planning for headland turning in open fields has been extensively studied and integrated into commercial autoguidance systems, the existing methods primarily address scenarios with ample headland space and thus may not work in more constrained headland geometries.

Published:

A small team of harvest-aiding mobile robots (FRAIL-bots) is being designed to aid large teams of human pickers in commercial strawberry harvesting by providing them with empty containers and transporting containers filled with harvested crops to collection stations at the edge of a field. The collective operation of these robots can serve requests for point-to-point transport in real time. The goal is to improve pickers’ job cycle by dramatically reducing non-productive walking and unloading times. To do so, individual FRAIL-bots with limited amounts must be dispatched and routed dynamically, in order to optimally match the dynamic and stochastic spatiotemporal distribution of real-time transport requests and resolve any spatial and resource sharing conflicts in the field correspondingly.

Published:

An emerging trend in agricultural field operations is the deployment of supervised autonomous teams of cooperating agricultural self-propelled machines. During such operations several machines (Agricultural Primary Units - APUs) perform the main field task (e.g., spraying, harvesting), and other machines (Field Service Units - FSUs) provide in-field logistics support, i.e., they transport working materials (chemicals, crop) between APUs and other units stationed outside the field. The same concept is being researched for robot-aided harvesting of specialty crops. For example, in strawberry harvesting, each picker (APU) harvests and fills up a tray; a mobile robot (FSU) travels to the picker and when their tray is full, it transports it to a field unloading station. Reactive scheduling policies for FSUs (go to a picker when tray becomes full) are not efficient, because FSUs may have to traverse large distances to reach pickers, thus introducing large waiting times.

Published:

Published:

As an agricultural robot navigates in an orchard following a nominal path consisting of waypoints, it may encounter unknown static or dynamic obstacles. When that happens, the robot must generate in real-time feasible trajectories to avoid the obstacles with minimum deviation from the nominal path. In this work, we address operating scenarios where the robot follows coarse routing waypoints obtained from a task-level planner. Also, we assume that the robot has adequate sensing to detect obstacles, and accurate localization capability, and must replan its path online, as new static or dynamic obstacles are sensed. Under the above conditions, a semi-reactive trajectory generation method that operates in a Frenet-Serret Frame is adapted to compute a set of smooth trajectories that can be followed by the robot, given the estimated robot state, sensed obstacles, and vehicle nonholonomic constraints. Then, the algorithm eliminates the trajectories that will interfere with the sensed obstacles and those that would result in violation of the maximum turning curvature, speed, and acceleration of the robot. If there are no remaining trajectories in the set, the robot will wait at the current location until a feasible path is achieved, after the obstacles are cleared. Otherwise, the planner will select an optimal plan that minimizes a weighted sum of the trajectory’s jerk and deviation from the nominal path, over the entire trajectory, as well as the assigned traversal speed of the last point in the trajectory. Finally, an existing model-based path tracker is implemented to follow the selected trajectory. As a first step, we implemented the navigation module with the proposed methodology in a simulated vineyard, with small-sized obstacles (that provide space for the robot to pass between them and the crop row) randomly distributed inside rows and headlands. The simulation results indicate that the robot can maneuver successfully and avoid the obstacles while executing a pre-assigned route. The navigation module was also developed into a ROS package. The functionalities of obstacle sensing, trajectory planning, and path tracking will be integrated and implemented on an existing custom-built robot platform to evaluate the navigation performance during a vineyard scouting task. In the evaluation experiments, static obstacles will be placed near the way points of the test path. Also, people will walk near the nominal path to evaluate the system in the presence of dynamic obstacles.

Published:

With the rapid development of robotics technology in orchard operations, the demand for intelligent and safe navigation of robots is increasingly becoming a necessity. Unlike open-field environments, orchard land use is more conservative, especially reflected in the narrow and irregular characteristics of the headland space. Also, the high value of orchard plants means significant losses in the event of robot collisions. Traditional agricultural vehicle path planning algorithms often fail to meet the safety operation requirements in orchard headland, and the optimization-based path planning algorithm proposed by the author cannot meet the requirements for online solving. Surrounding the above problems, this project proposes an online trajectory planning algorithm for agricultural robots based on convex optimization, to enhance the adaptability of robots to unstructured orchard environments and ensure the safety of operations.